NUHN TOP-FILL SLURRY SPREADER

Nuhn Top-fill Slurry Spreader Features

Tank

- 1/4″ tank

- Unibody construction, solid welds inside and out

- Full circle, tensioned baffles

- Circular shaped tank keeps center of gravity low as opposed to a mushroom shaped tank with the center of gravity very high

- 30″ square hole with 12″ riser

- Larger and easier to hit rather than a circle fill port

- Full light kit

- Lights are to the outside of the tires and are designed to break away if they hit something

- Three tank clean-out doors

- In-tank wash system – garden hose hook up

- Nuhn tanks are sandblasted to bare metal, removing the mill scale

- Sandblasting is far superior to a chemical wash

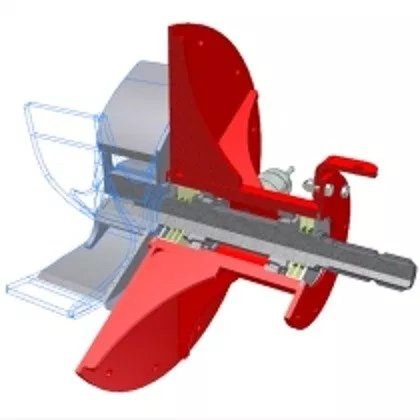

G-Force Front Pump System

- In-tank mixing without and moving parts

- The Nuhn front pump system creates a circulation from the rear of the tank to the front. All of the mixing is done at the bottom of the tank so solids and manure do not build up. Other tanks on the market circulate from the top, which allows for solids to build up at the bottom of the tank.

- G-Force tapered bearing and seal system

- The G-Force seal system uses a pressurized grease cup to force grease throughout the enclosed unit. It acts like a wheel hub and purges grease through the one-way seals. Running throughout the unit is a solid 1 3/4″ shaft, rolling in two tapered bearings spaced far apart for strength. The tapered bearings are protected by three lip seals at the liquid manure end of the unit, and two seals and the top end of the unit.

- Pressurized unloading creates even spread from full to empty

- Control valve adjusts spread from light to heavy

- The Nuhn valve cylinder is on the front of the tanker spreader, so it is visible by the operator to know the position of the valve as opposed to where the cylinder is on the top or rear of tank, which is out of sight

- Volume control feature allows for additional attachments and a low spread pattern

- 1000RPM or 540RPM constant velocity PTO

- Most tanks on the market use a standard PTO shaft. If the tractor turns at 45°, the combination of angles in both universal joints must bend an equivalent of 45°. The best geometry is achieved when the distance between the draw pin and the PTO of the tractor is the same as the distance between the draw pin and the shaft of the spreader pump. This gives 22.5° at both ends. When a long power shaft, such as 48” is used, very little bend happens at the spreader end, and the rest is made up at the tractor end. This creates excessive angles, chattering on turns and shortens PTO life. Also, the PTO in the tractor may be damaged.

- The Nuhn PTO uses a separate shaft from the pump to a bearing half way out the tongue. The shaft to the tractor is a constant velocity power shaft that has a double joint to maximize angles and reduce or eliminate wear and tear on the drive train.

Tank

- 1/4″ tank

- Unibody construction, solid welds inside and out

- Full circle, tensioned baffles

- Circular shaped tank keeps center of gravity low as opposed to a mushroom shaped tank with the center of gravity very high

- Large, 5″ bubble type sight gauge on tank

- Extra inlet ports at front and rear of tandem models

- Full light kit

- Lights are to the outside of the tires and are designed to break away if they hit something

- Large 20″ Rear Door

- Nuhn tanks are sandblasted to bare metal, removing the mill scale

- Sandblasting is far superior to a chemical wash

Frame

- 1/4″ Solid construction frame

- Full cross members

- Nuhn full cross members create a cradle for the tank, and bridge the tank and the two side frame pieces together. Other systems with just the two rails and no cross members have no structural integrity between the two rails.

- Extra support where tandem joins frame

Frame

- 1/4″ Solid construction frame

- Full cross members

- Nuhn full cross members create a cradle for the tank, and bridge the tank and the two side frame pieces together. Other systems with just the two rails and no cross members have no structural integrity between the two rails.

- Extra support where tandem joins frame

8’6″ Tongue

- Long tongue creates better handling, stability, better visibility

- Available with either a clevis or pintle hitch

- 7000lbs jack

Tandem

- Solid alloy spindles

- Nuhn spindles are welded directly into the main beam, eliminating weak points. Most tanks in the industry have its spindles mounted with a series of several parts on the end of the beam.

- Heaviest axle in the industry

- Large diamond tread tires

- Optional Radial tires available

- Most spreaders in the industry are approximately 13’ wide compared to the Nuhn tank which is 11’11” wide. This narrower track gives stability and at the same time, matches the road width and tractor width. This makes the Nuhn Magnum better for traveling on the road.

- Grease bank on side of frame to allow greasing the internal parts of the undercarriage easily

Optional Self Load

- Nuhn invented this system 20 years ago. The Nuhn self-load system is switched hydraulically and the diversion is all incorporated into the front pumping system. The transfer areas are very short. This prevents solid materials from settling and in rare cases, blocking the discharge pumps. Other spreaders on the market have a much longer inlet pipe.

Optional Brakes

- Hydraulic calliper disc brakes on each wheel (4)

- Tank brakes activated by tractor pedal brakes

© BAMBAUER EQUIPMENT LLC. ALL RIGHTS RESERVED. 419-753-2275 Site by: Midnet Media