OUR BLOG

Since its establishment in 1962, Bambauer Equipment has had a true business story of hurdles and successes throughout the years. Although the company is now fully entrenched in the world of liquid manure application, things weren’t always this way. Through innovation, hard work, and determination, Bambauer Equipment has really made a name for themselves as a reputable and evolving company that has been able to persevere for generations. As a family-owned and -operated business, this feat is very important for the Bambauer family, its loyal employees, and its customers. As a way to reminisce, we wanted to share some highlights from Bambauer Equipment’s history to put into reference how far the business has come and what has made it the success story that it is today. It all started with Wayne and Nancy Bambauer, a humble, young farm couple living in rural New Knoxville, Ohio. Before starting their business, the couple first began with grain and livestock farming. Nancy worked for two years at a local rubber company, and with the money she earned, she bought the couple’s first corn planter. This eventually evolved into working with livestock equipment. From there, they moved to liquid manure spreading equipment, and the rest is history. When Bambauer Equipment was first established in ‘62, Wayne was only 25 years old, while Nancy was even younger at 23 years of age. Despite their youth, the pair were economically minded and understood the needs of their local farming community. As proof, we only need to look at the original title of their business: Wayne Bambauer, Clay Equipment Sales & Services. Northwest Ohio is one of the most important agricultural areas. Clay equipment company was seemingly the perfect business to establish in the area, as the demand was readily present for solutions to improve agricultural practices. Getting into the business so early in their lives even allowed the Bambauers to sell one of the first manure spreaders in the US, an 800-gallon Clay Honey Wagon, to an Ohio farmer. This was the start of specializing in liquid manure for sales in US and Canada. Despite their forward-thinking ingenuity, there were some rough patches in the company’s history that acted as setbacks to progress. One such setback occurred only three years after beginning the business. In 1965, one of Bambauer’s barns burnt down, causing a deterrent to the family’s progress. Without enough insurance to cover the damages, one of Nancy and Wayne’s two sons, Scott, rebuilt the barn in 1976, when he was just a freshman in high school. This stretch of being without a barn undoubtedly made farming and business more difficult. Yet, the business persevered. Another rough patch occurred throughout the 80s, a time when farmers were having difficulty obtaining loans for farming equipment . These setbacks were only temporary deterrents to the business’s growth though, as the Bambauer family was able to overcome these obstacles and continue the business into the 21st century. Thanks to family experience, loyal employees, and a low turnover rate, Bambauer is known for its collective skill in the industry and has been able to gain a lot of trust from farmers and commercial applicators across North America . Scott and Doug (sons of Wayne and Nancy) started working with the Clay Equipment when they were in grade school. Hard work was very much expected, with a strict schedule of waking up at 4AM to take care of livestock and getting on the school bus by 7:45AM. Working for 50 cents an hour, both boys got their hands dirty often. Scott as young as 6 years old was installing knives on silo unloader augers. As one of Scott’s earliest inventions, “The Trucktor” came to life during his time in the high school Vo-Ag program. The rear half was a Massey Harris tractor, and the front half was an International large gas engine, one ton truck. Doug very much enjoyed working on the farm but loved playing basketball in between times. Additionally, the business’s ability to innovate in the liquid manure industry has also been a huge factor in their push for success. Between their well-known Red Dragster Hose – which increases both flow and product life span, The Big Stick – which allows for efficient manure suction with the added feature of remote-control technology, and Bambauer’s new Watchdog Controls technology – which allows a farmer to control a whole line of manure pumps without the need to man individual valves, Bambauer Equipment has helped to make manure spreading easier, quicker, and more efficient than ever before. Thanks to the hard work and innovation of the family, Bambauer Equipment has been successful enough to transcend generations. What first started with Nancy and Wayne, has now been passed to their sons, Scott and Doug. Following them, the mantle will be passed to a third generation. This third generation is made up of Scott’s two daughters, Gina and Ashely, and their two husbands, Jack and Corey, who are already well on their way to making the business better than ever. Bambauer will surely continue its efforts to innovate and push farming equipment further into the future. Bambauer Equipment has outgrown their office space and is researching the space needed to keep steadily growing in their efforts, which is really exciting for the family. All this goes to show that hard work, family-values, and innovation can pay off in ways that we may not even imagine in the moment. What may start as a humble effort to make money, can blossom into generations of pride and success in a business that you’ve all built together. Bambauer Equipment is truly an excellent example of a dream coming to life.

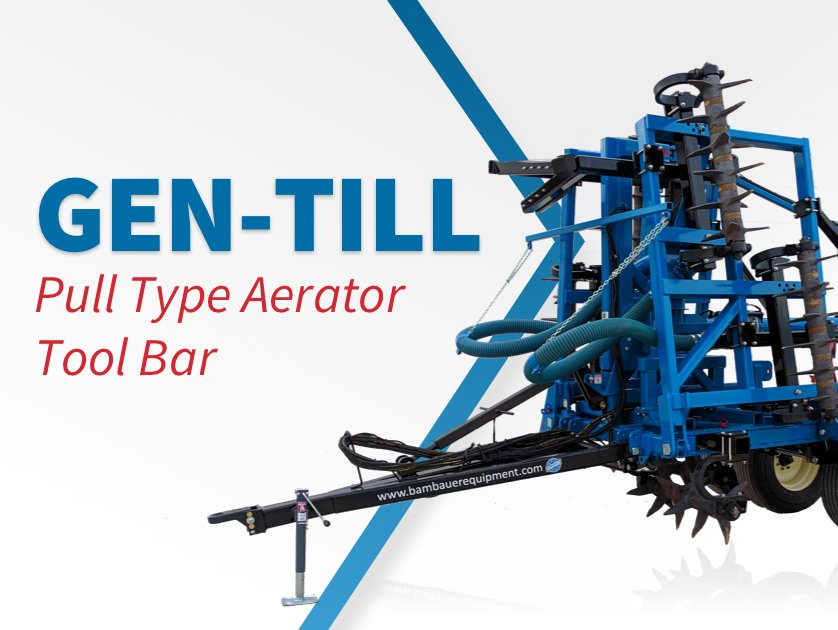

Tilling has been an element in farming for thousands of years from the early cultivation of human and draft-animal methods to the much more efficient mechanical methods commonly used in today’s farming practices. Needless to say, the technology has come a long way. But, just because modern aeration has vastly improved the rate of distance that can be covered doesn’t mean the technology has stopped evolving. On the contrary, many new options have arisen over the last 20 years that further optimize the process by instead focusing on the quality of the tilling and the durability of the tools. T he Gen-Till line of aerators is a huge factor in that push for further optimization. Gen-Till vertical tillage aerators are designed for conservation tillage but go a step further than the straight no-till method. Gen-Till technology strikes a balance between maintaining soil stability and breaking up soil for deeper nutrient enrichment. This can be an important preparatory step for fields, as it allows manure, water, organic matter, and important microorganisms to breach the top layer of the soil and integrate themselves into deeper layers for abundant root nutrients.

Farmers have relied on manure fertilization for almost as long as farming has been around. Technological advancements have made spreading manure easier throughout the years with new concepts like dragline systems that reduce the amount of soil compaction by eliminating the need to drive heavy tanks full of manure back and forth in the field. The reduced weight of dragline systems also allows operators to get into the field earlier in the season without fear of damaging wet fields. The invention of the manure pump allows for faster spreading than ever before. Now the practice has reached an all new level of efficiency. Thanks to the rise of digital technology, even the practice of managing pumps has become seamlessly integrated into a handy phone application. Before such an app was invented, farmers would have to hire workers to monitor each pump and control the flow to maintain optimal pressure and prevent spills. However, Bambauer’s Watchdog application makes this disjointed process a thing of the past, bringing all of the control and information right to your fingertips. Essentially, each pump in the sequence is outfitted with sensor technology to monitor the flow and overall mechanical efficiency of each pump. These integrated sensors then remotely transmit this data to the user’s app display, while the user in turn has full control over the operation of each machine. This allows for a seamless exchange between the user and their dragline operation.